Steering is a critical system of off-highway dump trucks. A failure of any component within the steering system is of major concern to stakeholders that may result in injury to the operator, extensive damage to equipment, extended loss of production and unscheduled maintenance requirements.

The objective of scheduled Condition Monitoring of steering components is to track wear growth over the components life cycle to predict point of failure prior to occurrence with consideration to acceptable risk.

It is imperative that an effective Condition Monitoring regime is implemented and maintained to eliminate the root cause of failure - progressive damage by wear. Regular monitoring of wear growth reduces the probability of near instant failure by fracture of the Ball Stud resulting in catastrophic failure with significant safety implications. This potential failure highlights the importance of regular measuring of deflection due to wear within steering system components.

Initial consequences of impact damage due to deflection include degradation of the hard surface coating by plastic deformation, surface fatigue, spalling and delamination.

Additional wear debris and excessive material loss between surfaces result in exponentially accelerated wear.

As wear increases, impact shock loading intensifies, increasing the likelihood of crack propagation below the hardened surface to within the parent metal. The structural integrity of the component is now compromised.

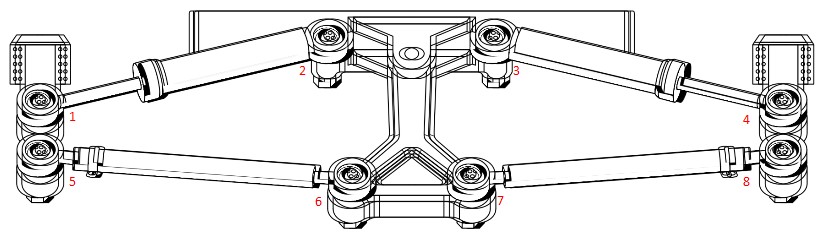

XAXIA enables Simultaneous Measurement of 8 x Critical Points of the Steering System

In most instances, if Ultra-sonic crack testing identifies cracks within ball studs, excessive impact and shock loading between surfaces of the cylinder/rod end bearings and ball studs has been present signifying ineffective wear monitoring techniques have permitted the component to exceed its safe in-service life.

Live Testing/Visual Inspection of the steering system components whilst equipment is energized pose significant risk of crush and/or impact injury to the technician. The correct installation and use of dial indicators to measure deflection is a time consuming exercise and relies on a technician’s competence to obtain reliable and repeatable results.